BC modules are highly anticipated for their exceptional performance, but achieving mass production has been described as "hellishly difficult." However, supported by a stable supply chain, industry-leading flexible production lines, authoritative performance certifications, and confirmed orders, Gokin Solar has now successfully built a comprehensive large-scale, high-quality, and sustainable mass production capabilities for BC modules.

1. Supply Chain Assurance: Deep Collaboration with Industry Leaders Lays the Foundation for Mass Production

As an "integration expert" in the photovoltaic industry, Gokin Solar’s core strength lies in accurately identifying and consolidating top-tier resources across the supply chain, thereby building a robust and reliable industrial ecosystem.

The outstanding performance of BC modules begins with a high-quality "heart"—the solar cell. Gokin Solar fully recognizes this and has established a long-term, stable, and deeply collaborative supply relationship with AIKO, a leading BC cell manufacturer. This ensures the high performance and reliability of the core materials used in BC modules, laying a solid foundation for module performance.

Beyond merely procuring cells, Gokin further enhances the power generation efficiency and long-term durability of cells within modules through proprietary encapsulation technology and enforcing material selection standards that are stricter than industry norms. This model of "strong collaboration + independent innovation" is the key supply chain guarantee that enables Gokin’s BC modules to achieve rapid mass production while maintaining high-quality output.

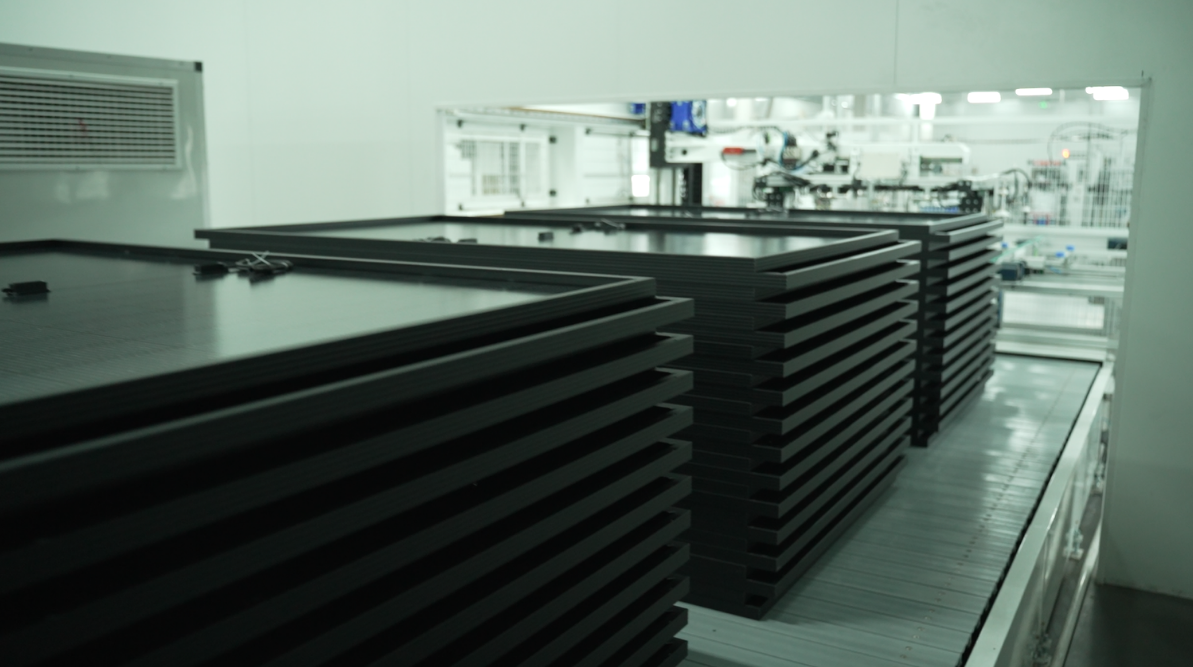

2. Manufacturing Revolution: "Versatile Production Line" Showcases Flexible Smart Manufacturing Strength

Mass production capability is the key to product commercialization. Gokin Solar has restructured and optimized its manufacturing processes, creating a unique versatile production line.

This line can quickly adapt to produce modules for various applications, with switch times between different product types shortened to 12 hours.

These highly flexible manufacturing capabilities and efficiency support the large-scale, high-quality production of Gokin’s BC modules while significantly reducing equipment and operational costs. This gives Gokin’s BC modules a cost advantage and market competitiveness right from their initial stages.

To some extent, this also demonstrates that parallel multi-technology routes are not a burden for Gokin but rather serve as a buffer against market uncertainties.

3. Authoritative Certifications: Among the World’s First to Earn A+ Grade Anti-Shading Certification

Performance advantages must be backed by robust data that withstands rigorous testing. At the SNEC exhibition in June, Gokin Solar successfully received the world’s first 2PfG 2926 A+ grade anti-shading certification from the internationally authoritative testing agency TÜV Rheinland.

Gokin’s BC modules feature full-scenario anti-shading capabilities that minimize power generation losses. This gives them a unique advantage in applications with high demands for low-light performance, such as agrivoltaics (crop shading), snow-covered solar farms (snow accumulation), BIPV (architectural obstructions), etc.

In addition to this groundbreaking A+ certification, Gokin’s BC modules also hold the highest Class A fire safety certification and have secured all necessary international certifications (such as CE and TÜV), meeting the global market entry requirements.

4. Market Validation: Fulfilled Orders Demonstrate Mass Production Capability

The ultimate test of mass production capability lies in market validation and customer trust. The exceptional performance and reliable quality of Gokin’s BC modules are gradually translating into real orders and successful project deliveries.

The on-time, high-quality, and complete fulfillment of existing orders fully demonstrates that Gokin’s end-to-end BC module mass production system, from production planning, material supply, and manufacturing execution to logistics, is operating efficiently.

Over a year of solid market cultivation has cleared key obstacles for Gokin’s BC modules to transition from the lab to large-scale production: stable supply chain foundation, high manufacturing barriers, authoritative product certifications, closed-loop market validation....

Thus, we confidently declare that Gokin Solar has fully established the capability for large-scale, high-quality, and sustainable mass production of BC modules and is translating this capability into a significant competitive market advantage.

This not only reflects Gokin’s technological prowess but also marks a victory for the company’s strategic focus and operational excellence. Looking forward, we will continue to prioritize customer needs and drive Gokin’s BC modules to achieve even greater success in global markets.